Infomation

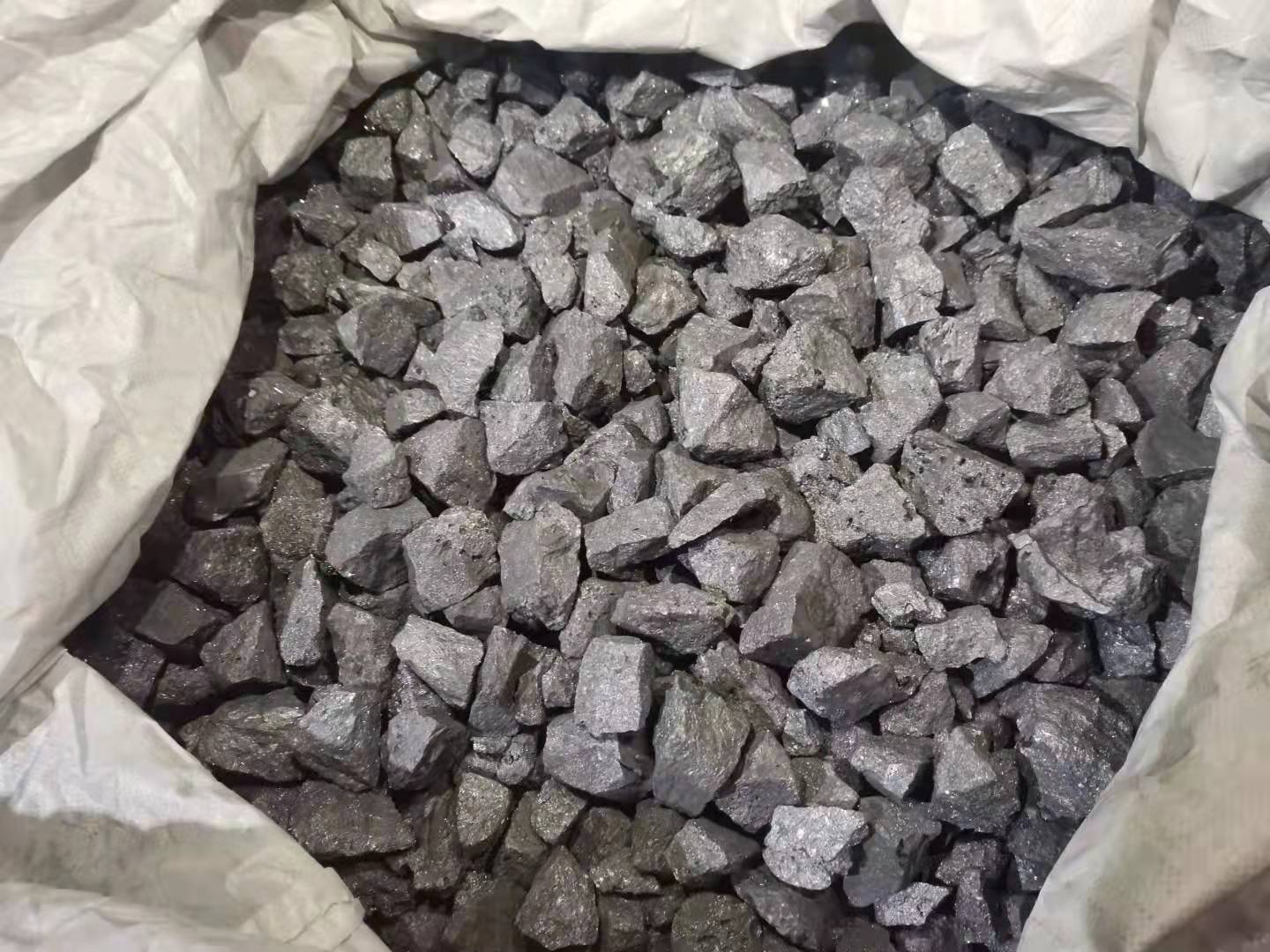

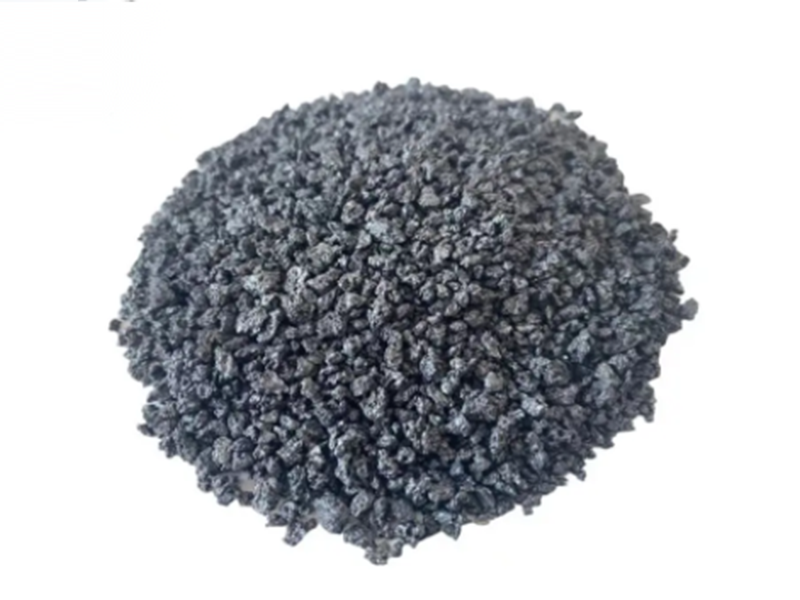

Silicon manganese alloy is an alloy composed of manganese, silicon, iron, and a small amount of carbon and other elements. It is a widely used and high-yield ferroalloy. Its consumption ranks second among electric furnace ferroalloy products. Manganese and silicon in manganese silicon alloys have a strong affinity for oxygen. When manganese silicon alloys are used in steelmaking, the deoxygenated products MnSiO3 and Mn2SiO4 have melting points of 1270 ℃ and 1327 ℃, respectively. They have advantages such as low melting point, large particle size, easy floatation, and good deoxygenation effect. Under the same conditions, using manganese or silicon alone for deoxidation resulted in a burning loss rate of 46% and 37%, respectively, while using manganese silicon alloy for deoxidation resulted in a burning loss rate of 29% for both.

It has been widely used in steelmaking, with a production growth rate higher than the average growth rate of ferroalloys and even higher than the growth rate of steel. It has become an indispensable composite deoxidizer and alloy additive in the steel industry. Manganese silicon alloys with carbon content below 1.9% are still used as semi-finished products for the production of medium to low carbon ferromanganese and electro silicothermic manganese metal.