Infomation

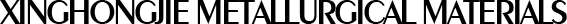

Alloy cored wire is used for steelmaking, purifying molten steel, changing the morphology of inclusions, improving the castability of molten steel, improving the performance of steel, and increasing the yield of ferroalloys, reducing alloy energy consumption, and reducing steelmaking costs, resulting in significant economic benefits.

Product advantages:

1. Change the composition and morphology of inclusions in steel to improve its mechanical properties.

2. Reduce and eliminate the blockage of the water inlet of continuous casting steel. After feeding a calcium silicate wire for calcium treatment, the high melting point solid Al2O3 and aluminum silicate are transformed into calcium aluminate. Due to their low melting point, they are in a liquid state at the casting temperature, thus avoiding the aggregation of the water inlet and eliminating the blockage of the water inlet.

3. The recovery rate of alloy elements is improved and stable. The usual calcium recovery rate is 1% -3% by the addition method, 5% by the powder spraying method, and 10% -30% by the wire feeding process.

Steel bracket iron cage or packaging according to customer requirements

Specifications:

model Main components Wire diameter(mm) Steel strip thickness(mm) Core powder quality(g/m) CaSi Ca20-30% 13 ± 0.8 0.4±0.05 220 Si50-60% Note: Produce alloy wires of other specifications according to customer needsCaFe Ca30-32% 250 Fe68-70% SiAl Si25%min 160 Al35%min